stretch wrap machine repair near me: Avoiding Common Wrapping Errors for Better Load Stability

Just How to Determine Usual Repair Problems in Stretch Wrap Machines and When to Seek Professional Assistance

Stretch Wrap makers are essential for efficient packaging operations. Nonetheless, they can experience different problems that hinder performance. Operators must be watchful in identifying signs of malfunction, such as inconsistent movie stress or unusual noises. Recognizing these typical repair service troubles is vital. Knowing when to look for expert help can make a significant difference. The nuances of troubleshooting and maintenance are worth exploring better.

Comprehending the Fundamentals of Stretch Wrap Machines

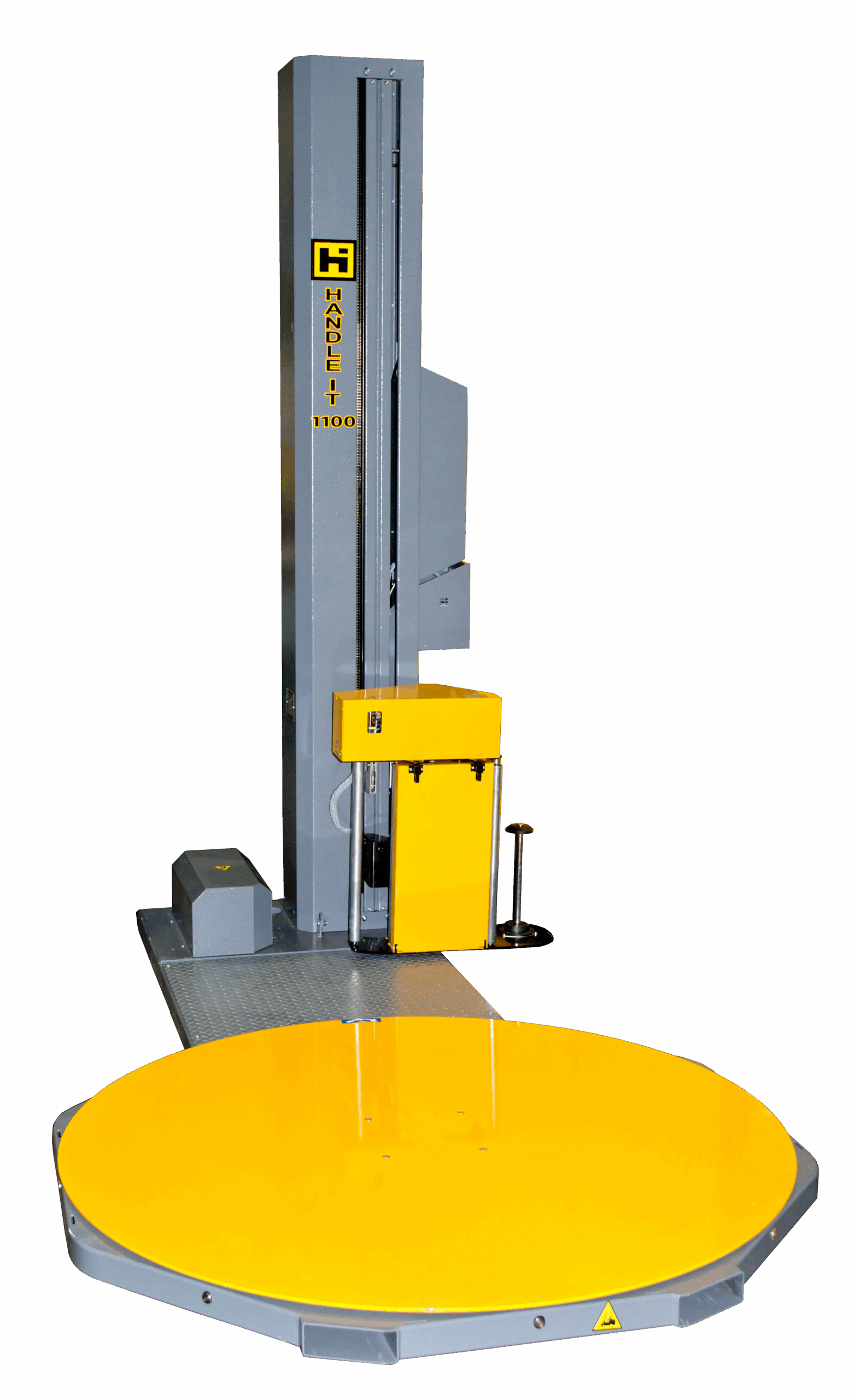

Stretch Wrap devices are crucial devices in the packaging sector, developed to safely encapsulate items for storage and transport. These devices utilize stretch film, which sticks to itself, creating a safety and limited layer around things. Typically, they come in various kinds, including handbook, semi-automatic, and completely automated versions, providing to diverse production requirements. The operation of a stretch Wrap device involves feeding the movie around the product, applying tension, and securing the Wrap, making certain that products remain steady throughout transit.Key parts of these devices consist of the film turntable, control, and carriage panel, each playing an essential role in the covering process. Effectiveness is even more improved by adjustable settings that enable individuals to tailor the stress and number of wraps. Recognizing these basics assists operators make best use of the machine's efficiency, making sure suitable packaging quality and decreasing the danger of item damages throughout handling or shipping.

Usual Concerns With Stretch Wrap Machines

Packaging efficiency can be substantially compromised by typical issues that arise with stretch Wrap makers. One prevalent issue is inconsistent film tension, which can cause insufficient tons stabilization and increased item damages throughout transportation. Furthermore, film damage often happens, interrupting the wrapping procedure and triggering delays in procedures. An additional concern is the improper alignment of rolls, which can lead to irregular wrapping and wastefulness of materials.Malfunctions in the control board might also impede performance, making it tough to adjust settings or keep track of efficiency. Electric problems, such as faulty wiring, can even more add to functional inefficiencies. Regular maintenance can help alleviate a number of these issues, making certain the device operates efficiently. Recognizing these common problems is crucial for operators, as timely treatment can protect against a lot more costly fixings and considerable breakdowns.

Indications Your Stretch Wrap Device Demands Repair Service

When a stretch Wrap equipment shows uncommon sounds during operation, it may show underlying mechanical problems. Furthermore, inconsistent film stress and frequent downtime can further indicate that the machine calls for prompt focus. Identifying these indicators early can assist protect against pricey repair services and guarantee peak efficiency.

Uncommon Noises Throughout Operation

Unusual noises throughout operation commonly signal underlying concerns with stretch Wrap devices that require immediate attention. These audios might consist of grinding, squeaking, or clanking, which can show wear and tear on elements such as gears, electric motors, or bearings. It may be struggling with imbalance or insufficient lubrication if the device produces unforeseen noises. Overlooking these audio hints can lead to more damage and costly repairs. Operators must carry out normal examinations to deal with the resource and recognize of the noise immediately. Consulting the machine's handbook can supply details guidelines for upkeep and troubleshooting. If the trouble continues after standard checks, seeking expert assistance is advisable to ensure the machine's long life and optimal efficiency.

Irregular Movie Stress

Inconsistent film stress can considerably impact the effectiveness of stretch Wrap equipments, causing substandard lots stability and possible product damages. This issue frequently shows up as unequal wraps, where particular locations of the load are tightly safeguarded while others are loose. Operators may see that the stretch movie is either under-stretched or over-stretched, affecting its ability to comply with the tons. Furthermore, there might be visible indicators of changing or slippage during transport, showing that the movie is not supplying sufficient assistance. Such variances can arise from worn-out components, inappropriate calibration, or malfunctioning sensors. Resolving these issues promptly is vital to ensure peak machine efficiency and to avoid additional issues that can arise from insufficient covering.

Constant Downtime Issues

Frequent downtime problems can indicate that a stretch Wrap machine needs urgent repair work. These interruptions frequently indicate underlying mechanical failures or system malfunctions. Operators may discover enhanced regularity of jams, which interfere with the covering process and impede productivity. Uncommon sounds during operation can also work as red flags, suggesting that parts might be misaligned or worn. Additionally, inconsistent film application can bring about insufficient lots protection, triggering additional functional delays. Neglecting these signs might lead to extra extreme damages and costly repair work. Subsequently, it is essential for operators to monitor their equipments very closely and attend to any indicators of malfunction immediately, making sure reliable procedure and decreasing downtime in the future. Looking for expert assistance may be necessary for complex problems.

Repairing Minor Issues

Fixing small troubles in stretch Wrap machines calls for an organized approach to identify and deal with concerns efficiently. Operators ought to begin by inspecting the power supply and making sure all connections are safe and secure. If the maker does not begin, verifying the circuit breakers and integrates can commonly expose basic electric issues. stretch wrap machine repair near me.Next, evaluating the stretch Wrap film for correct placement is essential. Imbalance can result in uneven wrapping and could need modification of the movie rolls. Additionally, drivers must find out here now check the stress settings; incorrect stress may cause inadequate Wrap quality.Routine upkeep, such as cleaning the rollers and guaranteeing they are without particles, can also avoid minor troubles from rising. Maintaining an eye on the equipment's performance can assist in recognizing patterns that indicate underlying concerns. By attending to these little issues quickly, drivers can keep peak performance and prevent bigger breakdowns

When to Call a Professional

Operators might locate themselves confronted with concerns that extend past minor modifications and regular upkeep. In such situations, identifying the best minute to call a professional ends up being crucial. If the stretch Wrap equipment continually fails to run appropriately despite fixing efforts, it may show a much deeper mechanical or electric fault. In addition, unusual noises, relentless error messages, or failing to Wrap tons safely are indicators that knowledge is needed.Furthermore, if the maker experiences constant failures or if components are harmed, an expert's intervention is required to avoid additional problems. When unfamiliar with certain repair work methods or when safety dangers are present, Operators needs to likewise take into consideration employing help. Inevitably, prompt expert support can not just fix complicated concerns however also prevent costly downtime and assurance optimal performance of the stretch Wrap maker.

Preventative Upkeep Tips for Stretch Wrap Machines

Often Asked Concerns

What Is the Ordinary Life Expectancy of a Stretch Wrap Maker?

Can I Make Use Of Different Sorts Of Stretch Movie on My Machine?

Various types of stretch movie can be used on a maker, but compatibility and performance may vary - stretch wrap machine repair near me. It's critical to seek advice from the maker specifications and maker standards to ensure the most effective results and stop potential problems

Exactly How Can I Enhance the Performance of My Stretch Wrap Maker?

To boost stretch Wrap device effectiveness, normal upkeep, suitable movie stress setups, correct positioning, and employee training are necessary. Additionally, updating components and lessening downtime via effective operations can significantly boost total performance and output.

Are There Any Particular Brands Recognized for Reliability?

Numerous brands are acknowledged for their reliability in stretch Wrap equipments, including Signode, Lantech, and Aetna. Users usually applaud these manufacturers for their longevity, efficiency uniformity, and solid customer support, boosting total operational efficiency.

What Is the Price Variety for Specialist Services on Stretch Wrap Machines?

The price range for professional fixings on stretch Wrap machines varies considerably, normally in between $150 to $1,500, relying on the intricacy of the issue, components needed, and the professional's expertise included in the repair work procedure. The operation of a stretch Wrap machine includes feeding the film around the product, applying tension, and securing the Wrap, guaranteeing that products stay steady throughout transit.Key parts of these devices consist of the film control, turntable, and carriage panel, each sites playing a vital duty in the wrapping procedure. Irregular film tension can significantly impact the effectiveness of stretch Wrap equipments, leading to subpar load security and potential item damages. Regular downtime issues can signify that a stretch Wrap device requires urgent repair. The ordinary life-span of a stretch Wrap device typically ranges from 5 to 15 years, depending on use, maintenance, and the quality of the maker. To improve stretch Wrap maker effectiveness, normal upkeep, ideal movie stress setups, appropriate alignment, and staff member training are essential.